Liquid Handling - Quadra4

The most reliable & user-friendly Liquid Handler

With over 40 years of experience in automated liquid handling, the Tomtec Quadra4 is the latest of a best in class rugged, cost effective liquid handling workstation for life science work-flows. The workstation is engineered around a reliable fixed-head air displacement syringe design which services a six station shuttle. The six stations can support a wide range of accessories for automating complex work-loads like solid phase extraction (SPE), and an optional plate-stacker can be used to queue up to 50 assays. With an easy to learn, user friendly graphical interface, the Quadra4 delivers unprecedented speed, flexibility, and precision.

See some of the Testimonials Tomtec has received on the Quadra4's performance.

Contact us at info@tomtec.com, or send us a Product Information Request

For questions regarding service, contact our Support

Financing available

Quadra4 Product Brief Quadra4 Replacement Tips

To see what Quadra is best for you, visit our Models page

Quadra4 Tech

GLP Compliance

Feature Set

Configurations

Accessories

1 - 2

<

>

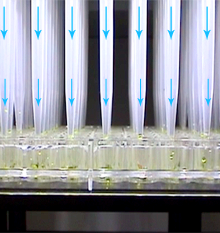

An important patented feature of our air displacement pipettor heads is the ability to blow low air pressure through the tip orifice under program control. We refer to it as a "Timed Dispense."

With the Timed Dispense function you clear the tips contents without touching the liquid in the plate. This function allows you to add the same reagent to multiple plates on the shuttle without contaminating the tips.

The Timed Dispense function is of extreme importance if you are pipetting both aqueous and organics. You can clear the organic vapors with a timed dispense function, and then pipette aqueous accurately. Competitive designs must stop and change tips when going from organic to aqueous pipetting.

The Quadra4 operates through an intuitive and flexible Graphical User Interface on top of a Windows OS. Simple and easy to learn, the Q4 software allows users to quickly program their protocols, increasing day to day productivity.

For over 40 years Tomtec has assisted the scientific communities research with the incredible accuracy of our Quadra4 pipetting heads. Our air displacement, positive displacement, and time/pressure heads will give users the most precise results for even the most complicated of laboratory protocols. Click to view a sample of our Accuracy Reports and Performance Qualifications.

1 - 2

<

>

GLP COMPLIANCE PROGRAM

FACTORY CERTIFICATION OF HEAD SPECIFICATIONS

Laboratories operating under the standards of Good Laboratory Practices (GLP), as defined by Section 40 of the Code of Federal Regulations Sections, 160 and 792, requires that all equipment used for the generation, measurement, or assessment of data shall be adequately tested, calibrated, and/or standardized, and that written records are maintained for such compliance.

In conjunction with providing our normal service and preventive maintenance programs, we also offer an opportunity to receive as requested a factory replacement head which certifies that the head is working within factory specifications. A continuing recurring program can be set-up to meet your specific needs based on your usage discounted accordingly for frequency. Proper documentation will be provided to meet the GLP requirements. For more information on our GLP Compliance Program please contact us at iinfo@tomtec.com

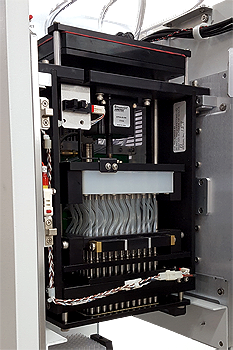

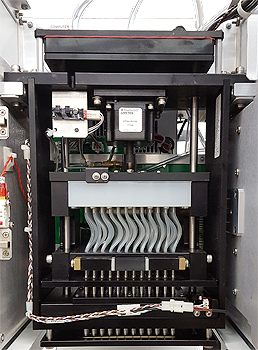

Each Quadra4 system is custom crafted in our Connecticut facility, to your exact needs. Our field engineers work with your research team to understand your work-flows and expectations, and then recommend the best possible solution at the best possible price. Once your new unit is received, our engineers come back and install, test and train your team on how to get the most value from your Tomtec investment. With both air displacement pipetting or positive displacement design available, in conjunction with an indexing microplate stage, the Quadra4 allows the support of complex pipette work-loads found on workstations that cost five-times its price. In addition, the optional automated plate stacker's provide true walk away assay automation. The following list provides an overview of capabilities and features.

Bioanalytical Applications

450uL tips with a cannula to access deep well plates

Aqueous, to organic, to aqueous, without a tip change

Manual or automated vacuum box

Stacker in-feed/out-feed for microplates and reservoirs provides walk away automation

Six station shuttle to support multiple microplates and reservoirs

SPE Liquid/Liquid extraction, optional positive pressure SPE

Ultrasonic tip washing

General Capabilities

Flexibility to support 96 well pipetting with either 450uL, 250uL, 50uL, or 20uL clear plastic tips

Automated serial dilution with either 8 or 12 tips

Pipette multiple reagents, within the same tip, using air gap separation to accelerate work-flows

Non contact dispensing

Reformat 96 to 384 and/or 1536 well assays

Precise Assay Automation

Precision 96 well positive displacement pipetting at 60uL to 0.5uL @ 2.5%

Precision 384 well positive displacement pipetting at 60uL to 0.5uL @ 2.5%

Automated 96 to 384 to 1536 reformatting

Tomtec, Inc. is a full service US manufacturer with its in-house CAD, tool & die design manufacturing and engineering support. This allows us to quickly design, develop and deploy custom manufactured components and/or fixtures to meet your demanding work-flow needs. Click here for details on the custom configurations of the Quadra4.

Tomtec offers a wide range of accessories and options for the Quadra4. This includes hot/cold plates with precision temperature control, programmable shaker nest, ultrasonic bath, stirring reservoir, contaminated tip removal fixture, alignment block, and much more. Click here for a full list of options.